Collaborative Robots Ai Uk

With a rapidly a growing interest in A.I., machine learning and immersive technology and how this relates to BIM - this WMBIM Region session will provide some 'future gazing' into current academic research, and a case study that undertaken for Digital Built Britain.

Meet the CoBots: Giving collaborative robots a human touch. 07 Jun 2017 Amit Katwala. Baxter and Sawyer are two of the most popular collaborative robot models (Credit: Rethink Robotics) Baxter is wider than a human, and almost as tall, with smooth red skin and long, powerful arms. Artificial intelligence and machine learning will allow the.

Collaborative Robots Ai Uk Youtube

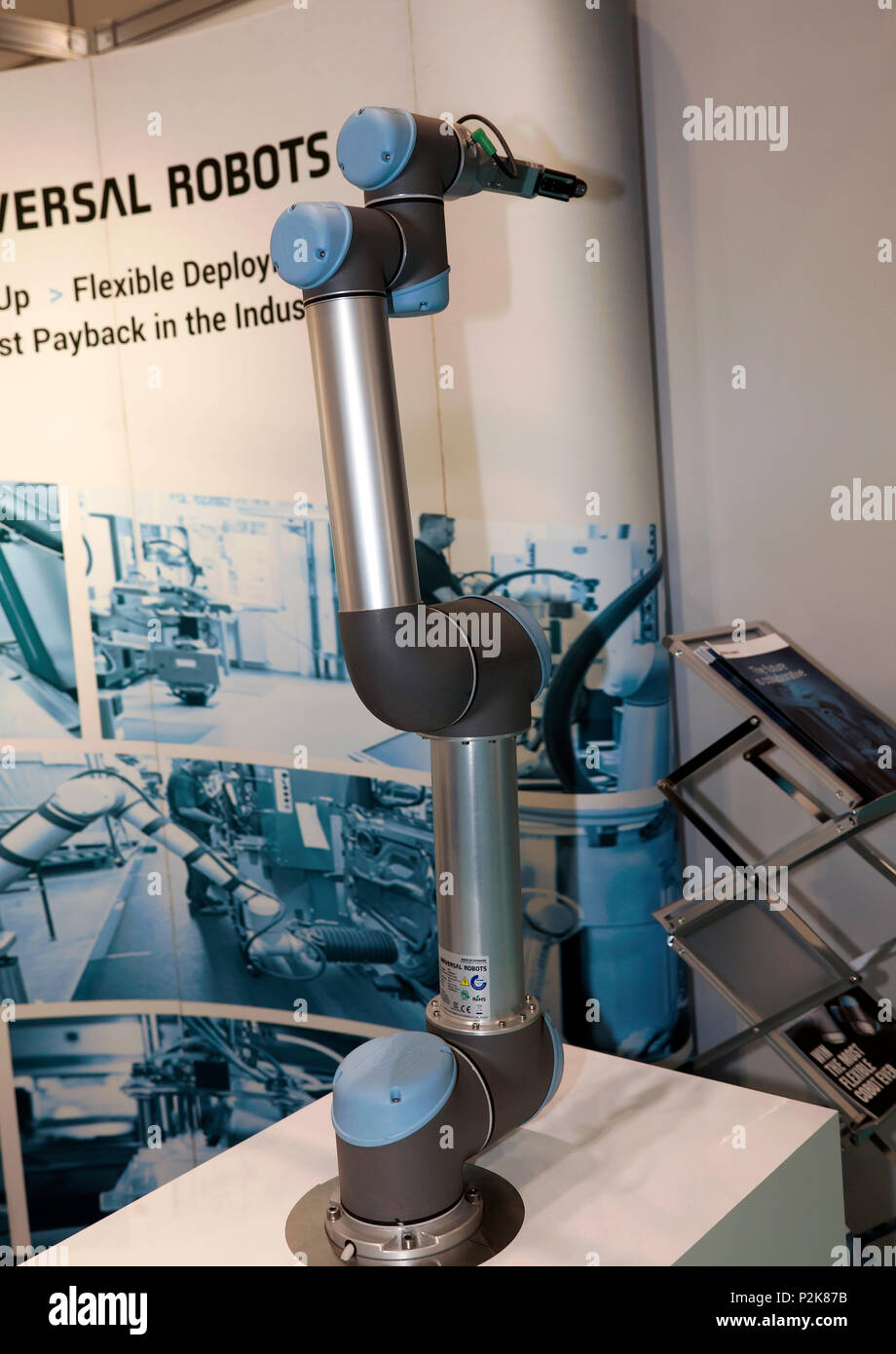

- A collaborative robot (also known as a cobot) is a robot designed to assist a human worker to complete a variety of specific (usually repetitive) tasks. Our range includes Universal Robot Industrial Arms. Hire a Collaborative robot from £65/day.

- The nascent collaborative robot market is set to grow by more than 60 percent this year according to an upcoming research report. From Interact Analysis. The industry was worth less than $400m last year but is set to grow to nearly $600m in 2018. Furthermore, growth is forecast to accelerate due to.

Session 1: (Dr Michel Valstar - University of Nottingham)

“Robots, Co-bots, A.I. Hype and the future of building design”

With an increasing focus on efficiency and digital innovation, there is growing development into robotics, machine learning and artificial intelligence, causing us to consider how the environment within future buildings will need to be adapted to accommodate a different types of ‘user’. A co-bot(from “collaborative robot”) is a robot intended to physically interact with humans in a shared workspace, and we must ensure the two can work harmoniously and safely together.

Currently buildings are designed for human occupation and meeting their needs – what impact will robotics have on the physical environment? What are the needs of a co-bot? How can co-bots help in the construction and maintenance of buildings? This session will show how academic research is moving towards preparing for this future, and look at how buildings will need to be designed in different ways to accommodate co-bots and humans safely, and what part BIM has to play in successful integration.

As part of the talk Dr Valstar will give a brief introduction into Deep Neural Networks for machine vision, the current driver between the hype of AI, winning the 2019 Turing Award.

Session 2: (Hadeel S. Saadoon - Coventry University Estates)

‘’Augmented Reality and Virtual Reality for Digital Built Britain – Research output by Vision Network for CDBB’’

Augmented reality (AR) and virtual reality (VR) technologies are widely used for gaming; marketing and for education and training. They also currently play a critical role in architecture, construction and engineering, all of which rely on imagery for communication. Vision Network is a research group funded by CDBB that was formed to explore AR and VR for digital built Britain. The research group investigated AR & VR’s role in enhancing the level of performance and digitisation for smart cities and smart construction at citizen, portfolio, organisation and project levels by looking at its role in the design, delivery, operation and integration phases and its impact on different stakeholders such as owners, builders, managers and users.

Hadeel Saadoon will present the content of the research project, funded by CDBB.

Agenda:

5.30pm Networking (Teas & Coffees)

6.00pm Event introduction from WMBIM Region chair

6.15pm Robots, Cobots and AI Hype – Dr Valstar

7.00pm AR and VR for Digital Built Britain – Hadeel Saadoon

7.30pm Questions and Close.

7.45pm Networking (Food)

EVENT KINDLY SPONSORED BY: Royal Haskoning

About the speakers:

Collaborative Robots Ai Uk Full

Michel Valstar (http://www.cs.nott.ac.uk/~pszmv) is an associate professor in Computer Science at the University of Nottingham, and member of both the Computer Vision and Mixed Reality Labs. He is an expert the fields of computer vision and machine learning, where his main interest and world-leading work is in automatic recognition of human behaviour using AI, specialising in the analysis of facial expressions. Valstar leads the work on co-bots and interactive AI at the University of Nottingham, including the development of a new robotic facility to study co-bots as part of the Smart Products Beacon. Previously he was a Visiting Researcher at MIT's Media Lab, and a Research Associate in the intelligent Behaviour Understanding Group (iBUG) at Imperial College London. He received his masters' degree in Electrical Engineering at Delft University of Technology in 2005 and his PhD at Imperial College London in 2008. He is the founder of the facial expression recognition challenges, FERA 2011/2015/2017, and the Audio-Visual Emotion recognition Challenge series, AVEC 2011-2019. He leads the Objective Assessment research area as the only non-professorial Research Area lead of a £23.6M Biomedical Research Centre, and was the coordinator of the EU Horizon 2020 project ARIA-VALUSPA. Valstar is recipient of Melinda & Bill Gates Foundation funding to help premature babies survive in the developing world. His work has received popular press coverage in The Guardian, Science Magazine, New Scientist, CBC, and on BBC Radio, among others. Valstar is a senior member of the IEEE. He has published over 90 peer-reviewed articles, attracting > 8,200 citations and attaining an H-index of 38.

Hadeel S. Saadoon (MSc. CMgr MCMI MCIAT ACIOB BRE BIM AP BREEAM AP) is Building Information Manager at Coventry University Estates and BIM4Estates Co-Chair. Managing the process of implementing BIM protocols across the University Estates to facilitate the Estates department services.

Supporting the Organisation and Capital Projects to develop Data Strategies and deploy effective Data Governance frameworks, processes& policies to improve the quality, management and exploitation of data and assets information.

Building Information Modelling is essential to help manage our information from inception throughout the life-cycle of projects and onto facilities management. I’m Working on implementing BIM in the core functions of the Estates which include Buildings Development and Facilities management to follow the UK Government BIM mandate. The BIM protocols help us to put in place a way of working that ensures the graphical and information output is consistently structured.

BIM is one of the digital technologies that helps the university to grow. Coventry University Group is rapidly expanding and has multiple locations across the UK including Coventry, London and Scarborough.

PLEASE NOTE THAT AS THIS IS A CATERED EVENT, PROVIDED BY OUR SPONSOR 'ROYAL HASKONING', PLEASE ADVISE US IF YOU CANNOT MAKE IT AS SOON AS YOU ARE AWARE.

- As companies aim to increase production, the demand for large-scale industrial robots is accelerating around the world.

- Today there are, on average, 84 robots for every 10,000 workers, according to the International Federation of Robotics. But robots' interactivity with co-workers could introduce the possibility of injury.

- On Monday Veo Robotics rolled out its new sensor technology, which gives these large-scale robots spatial awareness of every object and obstacle in their reach.

Collaborative robots, or cobots, have been working with humans on the factory floor for years, but when it comes to the large-scale industrial robots that can lift and move massive pieces of manufacturing, the danger to human workers is so great that the robots are bolted down to the factory floor behind fences so a human never comes near them.

That is starting to change as robotics becomes more widespread across industries.

Today there are, on average, 84 robots for every 10,000 workers in the U.S., according to the International Federation of Robotics. This places the U.S. second to Europe, at 99 units, and ahead of Asia, which to date averages 63 units (though the most roboticized country in the world is South Korea). While these next-generation robots are revolutionizing companies and expanding their bottom line, there is one very real caveat: Their increasing interactivity and mobility opens up the possibility of injury to human co-workers.

'[Large-scale industrial] robots in factories today are literally kept in cages,' says Clara Vu, co-founder and vice president of engineering at Veo Robotics, a start-up developing sensor technology to allow industrial robots to work safely side-by-side with humans. Vu, who has been building robots for more than 20 years,got her start working as an intern for iRobot when they were just a tiny start-up in the attic of a shopping mall. Vu wrote the programming language for iRobot's most well-known product, the Roomba, an autonomous robotic vacuum cleaner that debuted in 2002.

Vu says the cages are not to keep the robots in but to keep the humans out. 'The robots are bolted to the floor. They're not going anywhere. But ... the robot is not aware of the human, and it can be thousands of pounds, and it's moving really fast and people can get hurt.'

Veo Robotics plans to change that.

On Monday the Massachusetts-based company rolled out its new product, called Veo FreeMove, which gives robots spatial awareness of every object and obstacle in their reach. Its monitoring system signals a robot to slow or stop if an unrecognized, human-size object is closer to the robot than an acceptable protective separation distance, or PSD. When the obstruction passes, the robot will continue as programmed, allowing work to proceed without interruption.

The price tag: $30,000.

Partnering with four of the world's largest robot manufacturers — Kuka, Fanuc, ABB and Yaskawa — Veo retrofitted 3-D depth sensors and computer vision software into their robots and conducted trials with a number of automotive, household appliance and consumer packaged-goods manufacturers. For now Veo is using Microsoft Xbox Kinect depth cameras but is working on building its own sensors.

'The collaborative power and force-limited robots have been very useful for assembly of small things. What we would like to do is extend those advantages to all robots, regardless of the size. Whether it's a robot that can carry a car, or a robot that can carry a car door, or a robot that moves fast and positions things very precisely,' says Patrick Sobalvarro, Veo's CEO and co-founder.

There has been tremendous growth of robotics driven by the automotive sector, but robots are now moving far beyond heavy industrial manufacturing environments and into other industries, such as electronics, food services, law enforcement and health care — working as human assistants, not replacements, on the manufacturing floor.

The rise of the collaborative robot has been a revolution in business led by machines like Rethink Robotics' Sawyer. As companies increase production by reducing errors and improving quality and speed, the demand for these lighter-weight industrial robots has accelerated around the world: In 2017 worldwide shipments of these robots totaled around 387,000 units, up from around 294,000 the previous year.

Cobots are cheaper, lighter and more versatile than ordinary robots and physically interact with humans in a shared workspace. They are also designed to operate with limited guidance or, in some cases, completely autonomously, says Henrik Christensen, director of robotics at the University of California, San Diego.

By 2025 cobots will likely account for almost 35% of all industrial robots and exceed a market value of $9 billion, according to Loup Ventures, a venture capital firm that focuses on frontier tech. One of the main factors contributing to this growth will be a decrease in their price tags and an advancement of their capabilities in edge computing.

'It used to be that we would only see robots in very large enterprises, automotive and aerospace. Now through collaborative robots, it's made possible for very small mom-and-pop shop to adopt a robot. It's simple enough to program that they can basically buy one of these, they can install it, and they can use it within half an hour,' Christensen said.

According to McKinsey & Co., almost half the activities people are paid roughly $16 trillion in wages to do in the global economy have the potential to be automated. Activities most susceptible, says McKinsey, involve physical activities in highly structured and predictable environments, as well as the collection and processing of data. In the United States, these activities make up 51% of activities in the economy, accounting for almost $2.7 trillion in wages.

Veo's vision of making the large-scale industrial robot as free among humans in the factory as cobots is not one its management thinks is a threat to the human worker of the future. 'What we hear from every factory, every line manager ... is that they can't hire enough production workers,' Sobalvarro said. 'The production labor workforce is aging out, and one of the things we see as an advantage of our system is that physical strength will no longer be required for production workers. This company is predicated on the belief that production labor continues to be tremendously important in manufacturing.'

For more on tech, transformation and the future of work, join CNBC at @ Work: Human Capital + Finance Summit in Chicago on July 19.

- Diminished productivity, absence from work and health-care costs due to workplace stress can impact the U.S. economy by as much as $300 billion a year, according to some estimates.

- Working longer hours, engaging in workplace politics and being pressured to socialize outside of work are some of the biggest stressors, reveals a recent Bridge by Instructure survey.

- There are simple steps you can take to reduce stress and keep your mental health in check.